本设计分为五个部分:绪论,工艺流程的确定,设计计算、投资估算与效益分析。并附八张图纸:粗格栅图、调节池图、初沉池图、水解酸化池图、CASS生化池图、总流程图、平面布置图、高程布置图。通过毕业设计,分析目前高浓度污水处理技术和处理工艺等,设计高浓度污水处理工艺。绘制相关工艺流程图,设计出水满足相关标准的参数要求。根据高浓度污水特征水质指标数据,查阅相关出水标准数据,进行设计和计算。分析和了解高浓度污水处理的流程和方法特点,及处理工艺等,设计污水处理工艺流程。绘制相关构筑物工艺样图,出水满足相关标准的参数要求。

毕业论文关键字: 制革废水;CASS池;A/O脱氮池

High Concentrations of Sewage Treatment Technology and Design

Design general description:For the import of products demand for materials of leather is high-grade clothing and other daily necessities. Along with the economic development and the names of people living standard enhancement, the names of leather products is a sharp rise in the international market, leather and leather products has become the most active one. However, due to the leather industry is labor-intensive, serious pollution of industry, Europe and the United States Department of state have developed a relatively strict emission standards, not only so, the scarcity of labor, leather manufacturers, the number of employees are gradually reduced, corresponding to the increase of leather and leather products, the China leather industry development provides a good market environment. In recent years. In this graduation project, I chose the technology design of the tanning wastewater treatment technology to carry on the discussion to the topic.

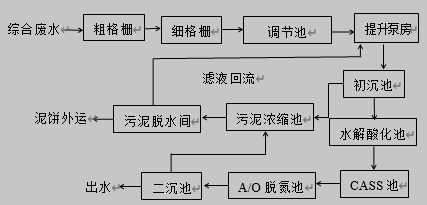

Integrated tanning wastewater treatment process can be pided into primary and secondary processing, such as necessary for Level 3. Level of processing mainly by a variety of grid, grid, sinking sand pool, regulating tank and sedimentation tank, etc., but also by chemical coagulation, air flotation technology operation department to strengthen the effect. The secondary processing unit is tannery wastewater treatment process, the most important unit operations, according to a biological system, the current domestic tannery wastewater treatment process is pided into physical and chemical treatment and biological treatment categories. In the design process, through the consult literature material, use the following method to deal with wastewater: a comprehensive sewage first through thick, (and then enter the sewage after the supernatant regulation and fine grille, water, peel, flesh solids ox hair removed into the aeration pool, and then use the pump to elevate to the initial sedimentation tank, the water solubility of mud and sand and other small solids precipitation, and on water quality, water and the pH adjusted. After the entering water hydrolysis acidification pool, improve the wastewater biodegradability by hydrolytic acidification CASS pool immediately and pool in aerobic sludge aerobic bacteria, protozoa and metazoa) fully mixing, adsorption and metabolic activities. The CASS treatment of sewage,ammonia nitrogen is still not standard, so in the following arranged A/O nitrogen pool, alternating after missing Aerobic and aerobic sections of the full denitrification and nitrification, the effluent through the two settling tank sedimentation can be discharged.

In the design of wastewater treatment plant design scale of 6000m3/d, design of water quality and quantity for Q=4500m3/d, CODCr=3000mg/L, pH:10~14, SS=3000mg/L, BOD5=1350mg/L, NH3-N=200mg/L, sulfide =100mg/L, chroma is less than or equal to 700 times. TCr=15mg/L. effluent quality reached < integrated wastewater discharge standard (GB8978-1996) > in tannery industry level standards, namely: pH:6~9; CODCr is less than or equal to 100mg / L, BOD5 = 30mg/L, SS = 70mg/L, NH3-N = 15mg/L = 1.0mg/L sulfide, chroma, equal to or less than 50 times, pH:6~9, Tcr≤1.5mg/L. Can row storage will precipitate generated outside the small selection according to the design parameters of chromium containing wastewater and alkali precipitation method. The drum is arranged under the liquid collecting groove separate collection of chromium containing wastewater, and then is perted to the plant chrome liquor storage pool, and then by the pump to chromium liquid reaction tank, add alkali (MgO) and steam heating to 70~75℃ and pH control in 8.5, static precipitation time 2h, chromium hydroxide precipitation, and then frame filter press pressed into chrome cake, the filtrate and the supernatant to comprehensive waste water aeration regulation pool. In this design, the choice of catalytic oxidation desulfurization. Its advantages are more complete removal of wastewater in sulfides, but the drawback is FeSO4 consumption is larger, produce a lot of black sludge. 日处理6000立方米高浓度污水处理技术与设计(2):http://www.751com.cn/huaxue/lunwen_43418.html