摘要本设计中齿轮泵为批量生产,根据齿轮泵加工工艺的特点,按照751点定位原理,设计镗削齿轮泵壳体齿轮型腔孔R43的专用夹具,计算夹紧力,分析定位误差;并根据工件材料、加工要求确定切削参数,计算切削功率,设计满足加工要求的专用机床。此设计的目的是为了在保证零件的数量和质量的同时更快更方便的达到图纸要求从而提高生产效率。通过对齿轮泵的零件图、结构、误差、精度要求的分析,制定出工艺并对工艺的夹具进行设计并在实际生产中能起到作用。设计中采用结构简单的螺旋快退夹紧机构,保证较高工作效率和稳定的夹紧力。21611

毕业论文关键词:齿轮泵;加工工艺;专用夹具;夹紧力;专用机床

Abstract

Gear pumps in the design is a mass production, according to the characteristics of the gear pumps processing technology, In accordance with the principles of the six-point positioning, design boring gear pumps R43 holes in dedicated fixtures, calculate the clamping force, analyze the positioning error; Determine the cutting parameters and in accordance with the requirements of the work piece material, processing, calculate the cutting power and design the specific machine which meet the processing requirements. The purpose of this design is to ensure that the quantity and quality of the parts and achieve the requirements of the drawings faster and more convenient in order to improve production efficiency. By the analysis of the fork parts diagram, structure, error, accuracy requirements, To develop a process and design process fixture ,which can play a role in the actual production. Used in the design of a screw retreat quickly clamping mechanism has simple structure, higher work efficiency and stability of the clamping force.

Keywords:Gear pumps;processing technology;the dedicated fixture;clamping force;the specific machine

目录

摘要 1

Abstract 1

1绪论 2

1.1课题依据 2

1.2 选题背景 2

1.3 课题研究的意义 3

1.4 文献综述 3

1.4.1 国内外专用机床的发展现状 3

1.4.2 国内外夹具的发展现状 5

2 专用机床的设计 7

2.1.基本参数的确定 7

2.2电动机、传动和减速系统的选择 8

2.2.1 电动机的选择 8

2.2.2传动件的设计 9

2.3其他设计 18

3 专用夹具的设计 19

3.1 定位基准的选择 19

3.2 实际夹紧力的计算和夹紧力方向 19

3.3夹紧机构的选择 21

3.4夹具体的设计 21

3.5 定位误差分析 22

3.6 夹具在机床上的定位 22

3.7夹具设计及操作的简要说明 23

总结 25

参考文献 26

致谢 27

齿轮泵壳体齿轮型腔孔2-R43加工专机及其夹具设计

1绪论

1.1课题依据

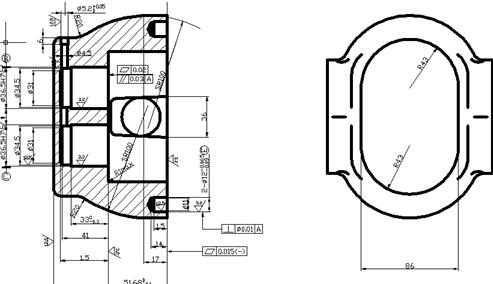

如图,根据齿轮泵壳体腔孔加工工艺特点,按照751点定位原理,设计齿轮型腔孔R43的的专用夹具,计算夹紧力,并根据工件材料、加工要求确定切削参数,计算切削功率,设计满足加工要求的专用机床。

图1.齿轮泵 齿轮泵壳体齿轮型腔孔2-R43加工专机及其夹具设计+CAD图纸:http://www.751com.cn/jixie/lunwen_13890.html